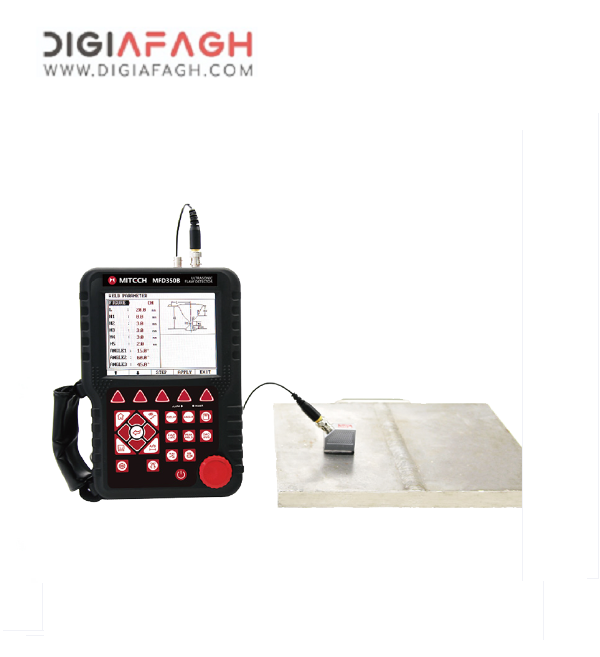

CDX-Ⅲ Magnetic Flaw Detector

Mitech CDX-Ⅲ Magnetic Flaw Detector

- brand : mitech

- category : Testing Equipment

Product Overview

MITECH CDX-Ⅲ multifunctional magnetic particle flaw detector is the self-designed magnetic participle flaw detector of MITECH CO.,LTD. With small size, light weight, easy operation, multifunction in one unit. The detector can equip A, D, E O four types of probes to realize the functions of magnetic clamp detection, electromagnetic yoke detection, cross magnetic yoke detection, ring detection. It is the necessary detector to do quality control, safety check, life evaluation in the fields of petrol, chemicals, metallurgy, shipbuilding, aviation, railway etc

Function & application

It is widely used in the industry of aircraft manufacturing, boiler and pressure vessel, electric, oil field, shipbuilding, turbine and combustion engine parts, mine, machinery, standard parts, oil pump, vehicle parts, bridging, chemical, railway, large mechanical components, steel structure equipment etc.

Working Principle

Magnetizing, put the workpiece in the magnetic field, connect electric to make it magnetized, if there are flaws(crack,slag), magnetic-curve will leakage on the flaws, when put magnetic participle on the workpiece, the magnetic field will catch the participle and pile up

Working Conditions

magnetizing time≤3s, clearance time≥5s

Instrument Features

l Show the shape, position, size, degree of defection and confirm the nature of defection, according to effect of magnetic field.

l Adopts new power mode, improves the accuracy of detection.

l Adjustable magnetic yoke makes the detector more practical.

l Accessory lights can be used in dark situation

l Four kinds of probes, improve the detection accuracy.

l Different magnetic method can test all parts of the workpiece.

l Humanized design, magnetizing switch is easy to touch.

l The detection speed is very fast.

l Can test the flaws between 0.5~3mm below the workpiece surface, for air hole the detection depth can up to 5mm.

l The magnetic participle can directly show the defection and detect the width of 0.1μm.

Operating Method and Attentions

l Working rhyme, when continuous working, magnetizing time≤3s, clearance time≥5s

l Check the voltage before using, over-high or over-low may damage the detection result.

l Make sure the probe is well connected with surface of workpiece, then press the key to magnetize, the result is in good situation.

l over-current protection circuit to avoid no load and temperature rise.

l When the detector is over-heat, stop using and find the reason.

l The detector and accessories should placed in environment of clean, dry and no corrosive medium.

l When repairing, please take care of the high voltage in the detector.

l When press the magnetizing key, do not turn off the switch or unplug the cable line.

l The shell must be placed on the ground.

l When there appears unsolved trouble, please deliver it to our company.

Instrument Maintenance

l Turn on the switch, the power indicator is not on, it might be the fuse damage or light damage.

l Magnetizing indicator is not on, it might be the indicator damage, the relay is not well connected or bidirectional triode thyristor damage.

Enter your opinion about this product