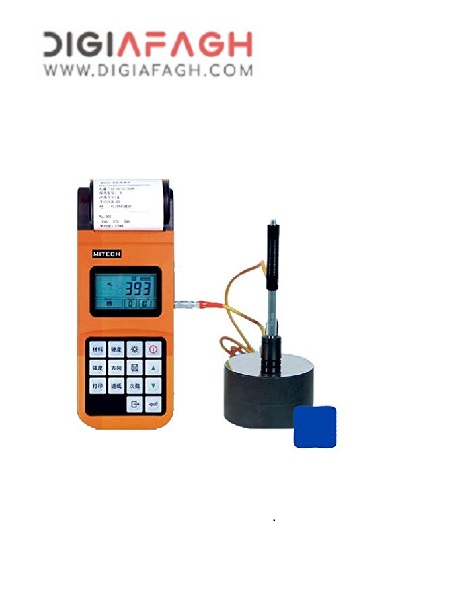

دستگاه سختی سنج الکتریکی MDW-ZS

Mitech MDW-ZS Electrical Webster Hardness Tester

- برند : شرکت MITECH

- دسته بندی : تجهیزات سختی سنج

سختی سنج الکتریکی Webster سری MDW-ZS، هوشمند طراحی شده اند و می توانند تست NDT سریع قطعه کار را در محل انجام دهند. الکتروموتور میکرو می تواند قدرت را اعمال کند، می تواند آزمایش را با فشار دادن سوئیچ انجام دهد، شدت کار پرسنل آزمایش را کاهش می دهد، فناوری جدید کالیبراسیون را بدون برچیدن و محافظ فرورفتگی اتخاذ می کند، دقت را بهبود می بخشد.با صفحه نمایش دیجیتال می توایند واضح تر بخوایند. بهترین انتخاب برای آزمایش محصولات دسته ای است و به طور گسترده در هر فرآیند تست تولید آلومینیوم، بازرسی پذیرش و بازرسی کیفیت محصولات، و همچنین در بخش های بازرسی کیفیت مهندسی و نظارت فنی استفاده می شود. یک وسیله ضروری در افزایش نرخ صلاحیت و صرفه جویی در هزینه است.

Function & application

l Confirm the workpiece is heat-treated or not,

l Whether the workpiece is made of improper alloy;

l Testing over-long or over-weight workpiece;

l Project acceptance of aluminum factories

l Do project acceptance in companies of windows, door and curtain wall.

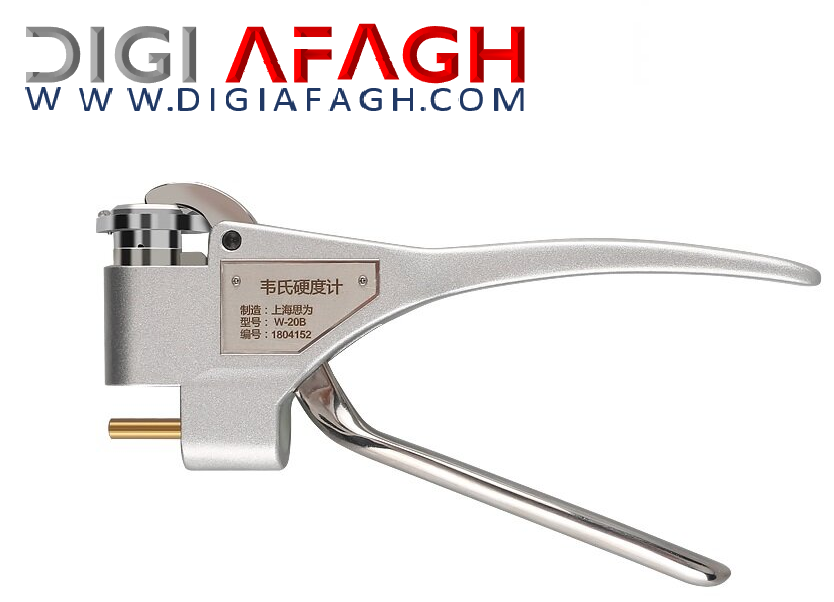

Working Principle

MDW-ZS series Webster hardness tester adopts indentation principle. Under pressure, the indentation is inversely proportional to the material hardness. HW is short for hardness of Webster, when the value is 16, it means the hardness is 16HW. The value can be read on the dial and can be changed into HV, HR. If the sample hardness is out of range, the needle will point at 20, if the range is too low, the needle will not move and it will stay at 0.

Working Conditions

The tester should be used in environment of clean, no vibration and no corrosive medium.

Instrument Features

l Portable and easy to read values, can do fast hardness test of aluminum alloy;

l Easy to learn, no high-skill skills of the operation requirements, the human operation of the measurement results less impact, very suitable for the production site for rapid hardness testing of materials;

l Can do fast NDT test on site of sale or work;

l Micro electrical motor can apply the strength, reduce the labor intensity of testing personnel;

l Indenter protection device can eliminate misoperation, rise the accuracy;

l Calibration without dismantle make the calibration more simple;

l The pre-pressing device makes the test in a vertical angle and avoid the inaccuracy of misplaced ;

l One key operation can test the hardness automatically;

l The distance of anvil and indenter can be adjusted, can test workpiece of various thickness .

Operating Method and Attentions

Operation

The tester has security lock to avoid misoperation, before measurement, press the switch for 1s, until indicator turns red to start measuring.

① Put the workpiece between anvil and pre pressing device, with a beep the reading will show the

Hardness.In order to ensure the accuracy of the measurement results and not to destroy the compression device and needle ,user need to keep the measured stable;

② Release switch, the needle will back to initial position

Notes:

Press the trigger when the left light turns red, indenter goes on, right light turns blue, when the indenter stop, blue indicator goes out. Release the switch the indenter go up, right side light turn red, when the indenter stop, red indicator goes out. 20s later, power auto-off, left red indicator goes out.

Instrument Maintenance

Instrument Maintenance

l Prevent contamination, use soft cloth to clean the dust or stain of the tester especially remove the contamination on the dial head or it will cause error.

l Prevent rust, when using pay special attention to its waterproof performance except clean it frequently, many parts will bear rust with water, the rust in the dial head will cause the instrument useless.

l Prevent falling off, the tester is made up of many precision components, falling off will result in permanent damage to some parts.

l Do not dismantle, all the components had already been put together properly in factory except calibration.

l If the instrument is not used for a long time, user should remove the battery in time to prevent the battery leak which may shorten the service life.

.svg.png)

فروشنده : آفاق تجهیزات آزمایش

دیدگاه خود را در مورد این کالا وارد نمایید.