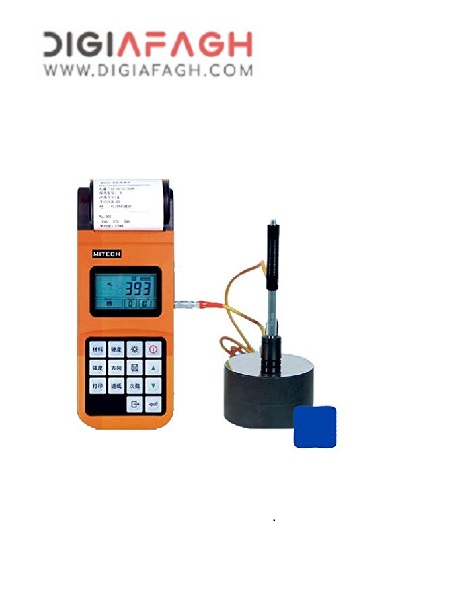

دستگاه سختی سنج قابل حمل MH310

MH310 Leeb Hardness Tester

- برند : شرکت MITECH

- دسته بندی : تجهیزات سختی سنج

سختی سنج قابل حمل MH310، بر اساس اصل اندازه گیری سختی Leeb، تست سریع و آسان در محل سختی مواد سری فلزی، پشتیبانی از تبدیل رایگان بین مقیاس سختی Leeb، Brinell، Rockwell و سایر موارد، از LCD بخش با کنتراست بالا برای نمایش استفاده می کند. عملکرد واضح و پایدار چاپگر حرارتی یکپارچه با سرعت بالا، که می تواند اندازه گیری های در محل را چاپ کند. این به طور گسترده ای در بازپخت، معتدل کردن، خاموش کردن، کنترل کیفیت برای قطعه کار استفاده می شود. تست سختی برای ماشین ابزار و شاسی خودرو. تست سختی قطعات غیر قابل جابجایی در محل کار؛ تست کیفیت برای سخت افزار، آهنگری، ماشین آلات و فولادهای ویژه؛ کنترل کیفیت برای فرآیند تولید دسته ای و غیره. کیفیت خوب و هزینه موثر، که یک انتخاب عاقلانه برای نیاز منظم به آزمایش سختی است.

Function & application

Die cavity of molds

Bearings and other parts

Failure analysis of pressure vessel, steam generator and other equipment

Heavy work piece

The installed machinery and permanently assembled parts.

Testing surface of a small hollow space

Requirements of formal original record for test results

Material identification in the warehouse of metallic materials

Rapid testing in large range and multi-measuring areas for large-scale work piece

Working Principle

The energy quotient is quoted in the hardness unit HL and is calculated from comparing the impact and rebound velocities of the impact body. It rebounds faster from harder samples than from softer ones, resulting in a greater energy quotient which is defined as 1000×Vr/ Vi.

HL=1000×Vr/ Vi

Where:

HL— Leeb hardness value

Vr — Rebound velocity of the impact body

Vi — Impact velocity of the impact body

Working Conditions

Working temperature:- 10℃~+50℃;

Storage temperature:-30℃~+60℃

Relative humidity: ≤90%;

The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium and heavy dust.

Instrument Features

Measuring range:(170~960)HLD

Error and repeatability :Impact device D 760±30HLD,±6 HLD;

530±40HLD,±10 HLD

Impact device DC 760±30HLDC,±6HLDC;

530±40HLDC,±10HLDC

Impact device DL 878±30HLDL,±12HLDL;

736±40HLDL,±12 HLDL

Impact device D+15 766±30HLD+15,±12HLD+15;

544±40HLD+15,±12HLD+15

Impact device G 590±40HLG,±12HLG;

500±40HLG,±12HLG

Impact device C 822±30HLC,±12 HLC;

590±40HLC,±12 HLC

Impact direction:vertically downward, oblique, horizontal, oblique, vertical upward, automatically identify

Material:Steel and cast steel,Cold work tool steel,Stainless steel,Grey cast iron,Nodular cast iron,Cast aluminum

alloys,BRASS(copper-zinc alloys),BRONZE(copper-aluminum/tin alloys),Wrought copper alloys

Hardness Scale:HL、HB、HRB、HRC、HRA、HV、HS

Paper roll: width (57.5 ± 0.5) mm, diameter: 30mm, long-term imports of paper to ensure long-term data storage

Display:High-contrast Segment LCD

Integrated data memory: 100 measurement series.(Relative to average times 32~1)

Battery: 6V( Ni-MH battery pack)

Power supply:9V/500mA

Recharge time:2.5-3.5hours

Continuous operating period:about 150 hours(with default brightness)

Communication:USB1.1

Based on the principle of Leeb hardness testing theory. It can measure many metallic material

One main unit can match to 6 impact devices

Support Steel ,when using D/DC sensor to test steel,it can show HB directly,no need to check manually.

High-contrast Segment LCD ,easy to use

Software calibration automatically.

100 groups (impact times 32 ~ 1) hardness measurements, each set of data includes single testing value, average value, measurement date / time, impact direction, frequency, material, hardness, and other information.

Real-time display the remaining battery power, charging progress is displayed while charging.

High brightness EL back-light display for easy use in dimly environment.

Automatic sleep and shutdown and other power-saving features

Integrated thermal printer with the instrument as a whole, and quiet operation, fast print speeds, you can print the test report on-site.

Equipped with PC software (optional), with functions of measurements transmission , value storage management, statistical analysis of the measured value, the print report of measured value, batch setting instrument parameters , to meet the higher requirements of quality for activities and management.

Small size, portable, , stable and reliable performance, suitable for harsh environment field operations, prevent from vibration, shock and electromagnetic interference.

Dimension:212mm×80mm×32mm

Operating Method and Attentions

1 Start-Up

----Insert the plug of the impact device into the socket of impact device on the instrument.

----Press the power key,now power is on. The instrument is in working mode.

2 Loading

Pushing the loading-tube downwards until contact is felt. Then allow it to slowly return to the starting position or using other method locking the impact body.

3 Localization

Press the impact device supporting ring firmly on the surface of the sample, the impact direction should be vertical to the testing surface.

4 Testing

----Press the release button on the upside of the impact device to test. The sample and the impact device as well as the operator are all required to be stable now. The action direction should pass the axis of the impact device.

----Each measure area of the sample usually need 3 to 5 times of testing operation. The result data dispersion should not more than mean value±15HL.

----The distance between any two impact points or from the center of any impact point to the edge of testing sample should conform to the regulation of Table 4-1.

---- If want accurate conversion from the Leeb hardness value to other hardness value, contrastive test is needed to get conversion relations for the special material. Use inspection qualified Leeb hardness tester and corresponding hardness tester to test at the same sample respectively. For each hardness value, each measure homogeneously 5 points of Leeb hardness value in the surrounding of more than three indentations which need conversion hardness, using Leeb hardness arithmetic average value and corresponding hardness average value as correlative value respectively, make individual hardness contrastive curve. Contrastive curve at least should include three group of correlative data.

|

Type of Impact Device |

Distance of center of the two indentations |

Distance of center of the indentation to sample edge |

|

Not less than (mm) |

Not less than (mm) |

|

|

D、DC |

3 |

5 |

|

DL |

3 |

5 |

|

D+15 |

3 |

5 |

|

G |

4 |

8 |

|

E |

3 |

5 |

|

C |

2 |

4 |

5 Read Measured Value

After each impact operation, the LCD will display the current measured value, impact times plus one, the buzzer would alert a long howl if the measured value is not within the valid range. When reaching the presetting impact times, the buzzer will alert a long howl. After 2 seconds, the buzzer will alert a short howl, and display the mean measured value.

6 Notification

---- Replacing the impact device must be done during Power off. Otherwise the main body could not identify the type of the impact device, and it may damage the circuit board of the main body.

----You could not save the current test value if the impact time is less than the presetting times value.

---- Only type D and type DC of impact device have the function of strength test option. You can not change the setting to strength testing when using other types of impact device. The setting would be set to hardness testing automatically after replacing the impact device whether the setting is hardness testing or not before.

---- Not all materials could convert to all hardness scale value. The hardness scale is reset to HL automatically after changing the material. So select material firstly before changing the hardness scale.

Instrument Maintenance

After the impact device has been used for 1000 to 2000 times, please use the nylon brush provided to clean the guide tube and the impact body. Follow these steps when cleaning the guide tube,

1.unscrew the support ring

2.take out the impact body

3.spiral the nylon brush in counterclockwise direction into the bottom of guide tube and take it out for 5 times

4.install the impact body and support ring when complete.

Release the impact body after use.

Any lubricant is prohibited inside the impact device.

.svg.png)

فروشنده : آفاق تجهیزات آزمایش

دیدگاه خود را در مورد این کالا وارد نمایید.