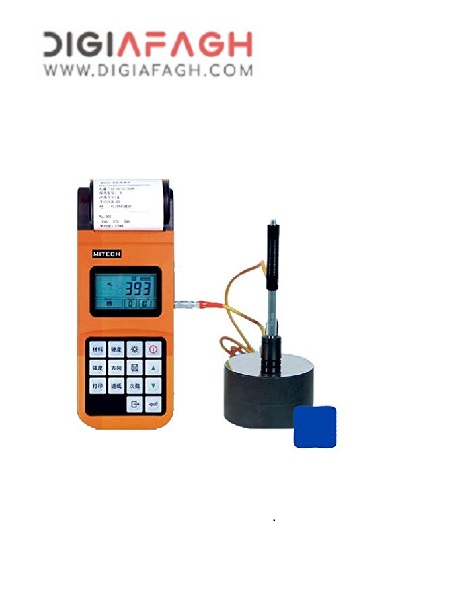

سختی سنج قابل حمل MH600 Leeb با طراحی هوشمند می تواند به سرعت و به راحتی برای تست سختی فلز در محل مورد استفاده قرار گیرد. حفاظت IP65، می تواند به طور موثر از روغن، گرد و غبار و سایر خوردگی در محیط های سخت جلوگیری کند. با صفحه نمایش LCD رنگی، همچنین می تواند نتایج آزمایش واضح را در نور کم و محیط نور خورشید قوی نمایش دهد، که تجربه بصری را تا حد زیادی افزایش می دهد. تابع کالیبراسیون چند نقطه ای specil برای تبدیل منحنی برای کاهش خطاها؛ می تواند به طور خودکار جهت اندازه گیری را در هنگام آزمایش شناسایی کند، به طور خودکار زنگ هشدار زمانی که خارج از محدوده است، برای برآورده کردن الزامات بازرسی با مواد جمع آوری شده با دقت بالا و چند زاویه و پشتیبانی از تبدیل رایگان بین سختی مقیاس طراحی کم مصرف با دو باتری AA، پشتیبانی از چندین زبان. به طور گسترده ای در پردازش و ساخت فلز، تجهیزات ویژه یا تجزیه و تحلیل شکست اجزای دائمی در خدمات، بازرسی و سایر زمینه ها استفاده می شود. به ویژه برای تست سختی بخش بزرگ غیر قابل جابجایی سایت مناسب است. برای بهبود نرخ عبور تولید و صرفه جویی در هزینه ابزار دقیق حرفه ای لازم است.

Function & application

l Die cavity of molds

l Bearings and other parts

l Failure analysis of pressure vessel, steam generator and other equipment

l Heavy work piece

l The installed machinery and permanently assembled parts.

l Testing surface of a small hollow space

l Requirements of formal original record for test results

l Material identification in the warehouse of metallic materials

l Rapid testing in large range and multi-measuring areas for large-scale work piece

Working Principle

The basic principle is to use an impact body of certain weight impacts against the testing surface under certain test force, then measure the impacting velocity and the rebounding velocity of the impact body respectively when the spherically test tip is located 1mm above the testing surface.

The calculation formula is as follows:

HL=1000×VB/ VA

Where:

HL—— Leeb hardness value

VB—— Rebounding velocity of the impact body

VA—— Impacting velocity of the impact body

Working Conditions

l Working temperature:-10℃~+50℃;

l Storage temperature:-30℃~+60℃

l Relative humidity: ≤90%;

The surrounding environment should avoid of vibration, strong magnetic field, co

Instrument Features

Based on the principle of Leeb hardness testing principle. It can measure the Leeb hardness of all metallic materials.

One main unit can match to 6 impact devices Automatically identify the type without calibration

Automatically identify the state of impact devices(connect,disconnect,error ,etc.).

Automatically identify the direction of impact devices (except G),360° comprehensive free measurement.

320 × 240 TFT LCD screen. information-rich, intuitive, clear display, adjustable brightness, easy to use in dimly lit environments and intense sunlight.

Basic (single-point) calibration and multi-point calibration function for convert curve,to reduce the test error.Hardness scales can be converted to HL,HRB, HRC,HRA, HV,HS,

Built-in Leeb hardness conversion function to converse HLD to HLC,HLG,HLDL,HLD+15,which is convenient for calibration and value conversion.

Preset up and low limit of hardness value , it will alarm automatically if out of range alarm, convenient for batch testings.

Chinese-English converting, menu operation, easy and convenient.

It can store 500 groups (impact times 32 ~ 1) hardness values, each data includes single testing value, average value, measurement date / time, impact direction, frequency, material, hardness and other information.

Two ordinary AA batteries, it can work for not less than 100 hours; automatic screen standby , automatic sleep, automatic shutdown and other power-saving features.

USB interface can do transmission measurements, value storage management, value statistical analysis ,printing the value report and batch setting the instrument parameters through the PC data-pro software, to meet the higher demand for quality assurance and management.

ABS plastic seal design, IP65 protection, which can effectively prevent oil, dust and other corrosion of harsh environments

Dimension:150mm×76mm×38mm

Operating Method and Attentions

1 Start-Up

----Insert the plug of the impact device into the socket of impact device on the instrument.

----Press the power key,now power is on. The instrument is in working mode.

2 Loading

Pushing the loading-tube downwards until contact is felt. Then allow it to slowly return to the starting position or using other method locking the impact body.

3 Localization

Press the impact device supporting ring firmly on the surface of the sample, the impact direction should be vertical to the testing surface.

4 Testing

----Press the release button on the upside of the impact device to test. The sample and the impact device as well as the operator are all required to be stable now. The action direction should pass the axis of the impact device.

----Each measure area of the sample usually need 3 to 5 times of testing operation. The result data dispersion should not more than mean value±15HL.

----The distance between any two impact points or from the center of any impact point to the edge of testing sample should conform to the regulation of Table 4-1.

---- If want accurate conversion from the Leeb hardness value to other hardness value, contrastive test is needed to get conversion relations for the special material. Use inspection qualified Leeb hardness tester and corresponding hardness tester to test at the same sample respectively. For each hardness value, each measure homogeneously 5 points of Leeb hardness value in the surrounding of more than three indentations which need conversion hardness, using Leeb hardness arithmetic average value and corresponding hardness average value as correlative value respectively, make individual hardness contrastive curve. Contrastive curve at least should include three group of correlative data.

|

Type of Impact Device

|

Distance of center of the two indentations

|

Distance of center of the indentation to sample edge

|

|

Not less than (mm)

|

Not less than (mm)

|

|

D、DC

|

3

|

5

|

|

DL

|

3

|

5

|

|

D+15

|

3

|

5

|

|

G

|

4

|

8

|

|

E

|

3

|

5

|

|

C

|

2

|

4

|

5 Read Measured Value

After each impact operation, the LCD will display the current measured value, impact times plus one, the buzzer would alert a long howl if the measured value is not within the valid range. When reaching the presetting impact times, the buzzer will alert a long howl. After 2 seconds, the buzzer will alert a short howl, and display the mean measured value.

6 Notification

---- Replacing the impact device must be done during Power off. Otherwise the main body could not identify the type of the impact device, and it may damage the circuit board of the main body.

----You could not save the current test value if the impact time is less than the presetting times value.

---- Only type D and type DC of impact device have the function of strength test option. You can not change the setting to strength testing when using other types of impact device. The setting would be set to hardness testing automatically after replacing the impact device whether the setting is hardness testing or not before.

---- Not all materials could convert to all hardness scale value. The hardness scale is reset to HL automatically after changing the material. So select material firstly before changing the hardness scale.

Instrument Maintenance

Instrument Maintenance

After the impact device has been used for 1000 to 2000 times, please use the nylon brush provided to clean the guide tube and the impact body. Follow these steps when cleaning the guide tube,

1.unscrew the support ring

2.take out the impact body

3.spiral the nylon brush in counterclockwise direction into the bottom of guide tube and take it out for 5 times

4.install the impact body and support ring when complete.

Release the impact body after use.

Any lubricant is prohibited inside the impact device.

Instrument Maintenance

Instrument Maintenance

.svg.png)

دیدگاه خود را در مورد این کالا وارد نمایید.