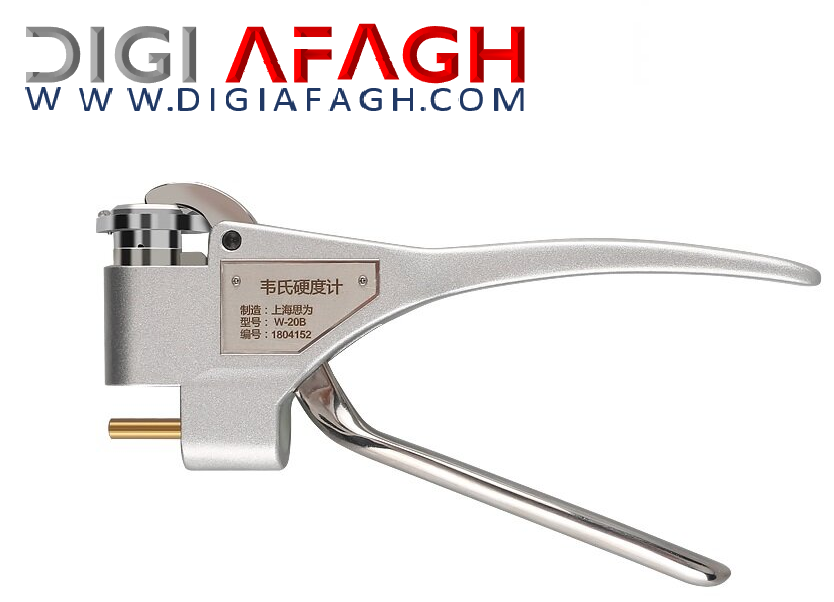

دستگاه سختی سنج اپتیکی پیشرفته MHBRVU-187.5 II

Mitech MHBRVU-187.5 II Advanced Optical Hardness Tester

- برند : شرکت MITECH

- دسته بندی : تجهیزات سختی سنج

سختی سنج اپتیکی پیشرفته Mitech MHBRVU-187.5II، بر اساس اصل مکانیکی فرورفتگی الماس یا کاربید سیمانی کروی با فشار دادن به سطح نمونه برای ایجاد فرورفتگی، با اندازهگیری عمق یا قطر مواد سهگانه سختی مواد برینل، راکول، وبکرز را اندازهگیری میکند. تورفتگی با ظاهر جدید، با ویژگی های کامل، مقدار سختی راکول را می توان به طور مستقیم توسط صفحه نمایش نوری خواند، مقادیر سختی ویکرز، برینل نیاز به جستجوی جدول دارند، عملیات آسان، می تواند نیازهای کاربران انواع تست سختی را برآورده کند. به طور گسترده ای در پردازش و ساخت فلز، تجزیه و تحلیل شکست مواد فلزی مختلف و زمینه های دیگر مانند کالج ها و موسسات تحقیقاتی استفاده می شود. نوع جدید ابزار تست چند منظوره برای فلزی و بخشی از تحقیق و تست سختی مواد غیرفلزی است.

Function & application

l Used for quality control in metal processing manufacturing

l Used for failure analysis testing of metallic materials;

l Demonstration experiment for education and teaching in Colleges and Universities;

l Hardness testing of materials in scientific research institutions

Working Principle

Brinell hardness test: Test force(F) is on the steel ball with certain diameter(D) , pressed on sample surface. After a period of time, cancel the force. The indentation diameter is get by measuring with micrometer ocular,thus to calculate the average pressure(N/mm²).Then we can get the Brinell hardness.

Rockwell hardness test is a vertex angle of 120 ° diamond cone or a certain diameter of the hardened steel ball as a pressure to the specified test force will be pressed into the sample surface, according to the sample surface indentation depth to be measured The Rockwell hardness of metallic materials.

Micro-Vickers (or Knoop) hardness test principle is that put the provisions of the positive pyramid diamond indenter into the sample surface(with fixed experimental force) and maintain a certain length (holding), and then unloading. Finally, there is a positive quadrangular pyramid or kenup indentation with a square surface on the surface of the specimen. Then we can attain the area of indentation via measuring the length of the diagonal by a micrometer eyepiece. Then the corresponding Vickers (or Knoop) hardness values are obtained.

Working Conditions

l Operation Temperature:18~28℃;

l Relative Humidity:≤65%;

l Clean environment, no vibration;

No corrosive media around.

Instrument Features

l Equipped with Brinell, Rockwell, Vickers three hardness test indenter, full-featured, widely used that can meet a variety of hardness testing needs of metal and non-metallic materials;

l Using high-end optical projection screen display hardness value, simple operation, easy to read;

l Test force of the loading, holding, unloading with semi-automatic control, high efficiency;

l Adjustable cold light source measurement system that can adjust the light source strength through turning the adjustment handwheel;

l Equipped with excellent performance of the carbide indenter with high hardness, wear resistance, good toughness, while high temperature, corrosion resistance to ensure that the instrument test value is accurate, stable and reliable;

l With seven test power, a wider range of testing, higher accuracy;

l Adopt diamond indenter, durable and accurate;

l Adopt high magnification optical sensing system and high precision photoelectric sensing technology, the test point positioning is accurate, the test result is more accurate;

l Consistent with GB/T230, GB/T231, GB/T4340, JJG144-1999, ISO 6508, ASTM E 10, ASTM E92, ASTM E18, ASTM E384, ASTM E103 and other relevant domestic and foreign standards.

Operating Method and Attentions

l Read the manual carefully before using the instrument. Learn the operation steps and attentions to avoid damage the instrument or personal safety accidents caused by improper operation.

l User should follow the operating procedures and calibrate the instrument repeatedly with the standard block before and after testing. If idled for a long time, the instrument should be calibrated several times after restarting, and then test the parts after the test result is stable;

l When the test force is applied to the test specimen, It is strictly forbidden to decline or raise the screw to avoid damaging the indenter.

l The use period of the hardness block is one year. The distance between two adjacent indentions center or the distance from the indentation center to edge of specimen is not less than 3mm. Too closely distance will affect the test result.

l Pay attention to palm the instrument for carrying to forbid falling across. Please pull out the power plug and fix well the measuring lever, counterweight r and boom before carrying.

Instrument Maintenance

l When replacing the fuse or removing the counterweight, please turn off the power first.

l When not in use for a long time, please cover the dust cover to prevent dust into the instrument interior. And the hardness block, indenter should be coated with antirust oil to prevent rusting after using.

l The hardness tester should be calibrated at least once a year to ensure its accuracy.

.svg.png)

فروشنده : آفاق تجهیزات آزمایش

دیدگاه خود را در مورد این کالا وارد نمایید.